Print and Finishing

At MetPrint, we understand that each printed item is important. Our lithography printing process ensures individuality and enables you and your product to stand out from the crowd.

Working with MetPrint brings you into our metal printing family and offers insight to our much-lauded service.

With a multicolour process that uses both spot colour and four colour to achieve optimal results time after time, your specifications are considered every step of the way to ensure your product hits the mark.

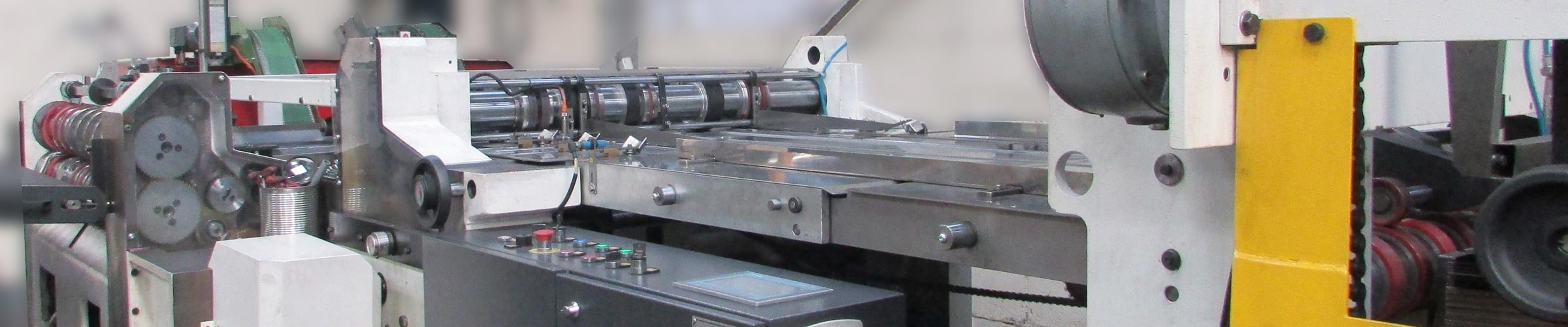

A recommended 1200mm x 1000mm maximum metal sheet size is used for tinplate, which, when complemented with our modern, customisable multicolour and colour matching printing facility and unrivalled industry experience, ensures your high standards of consistency and quality are met.

The decorative metal printing market proudly includes countless MetPrint pieces in sectors such as coating, chemical, automotive, marine, pharmaceutical, food and retail.

Using state-of-the-art Digital CTP (Computer to Plate) technology eliminates the use of conventional film, meaning your product benefits from increased sharpness, ultra-fine detail and a high-quality, high-definition image.

If it’s security printing and brand / product protection you require, MetPrint is well-equipped to produce complex and unique compositions to enhance exposure to your work and give you that all-important edge in the marketplace.

With market-leading tinplate design facilities capable of producing all manner of complex decorative designs, your printed product will benefit from the full MetPrint chain of expertise being located under one roof.

With a design studio offering reprographic support from initial artwork to final print, you are able to tailor designs to your exact specifications and work with us to assemble a print design suited to your budget.

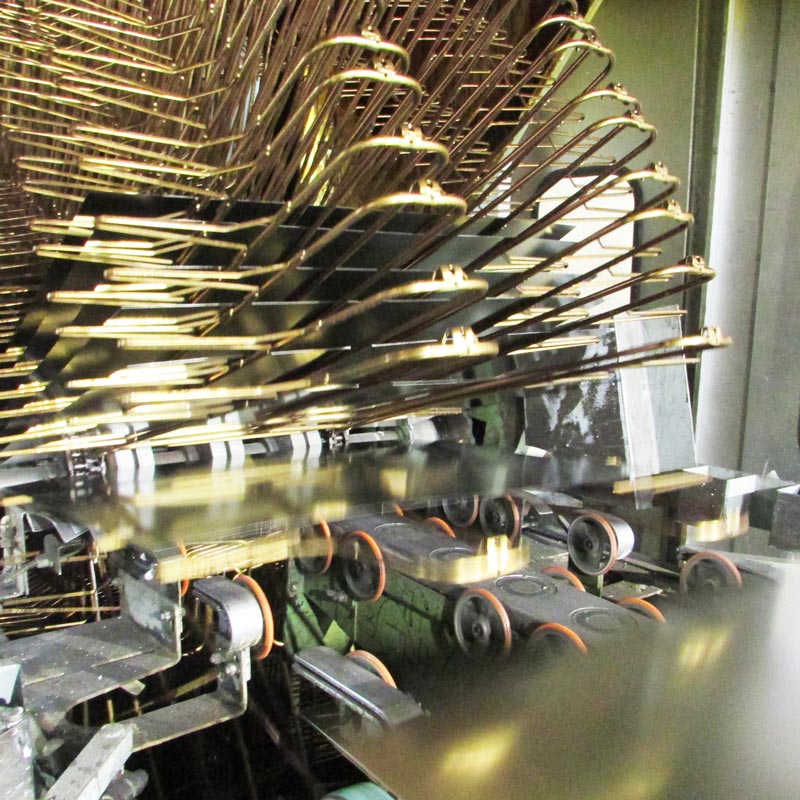

Though not wanting to give away all our metal printing secrets of success, we’d love to tell you a little about our finishing processes

With an ability to offer various external and internal finishes, what will you opt for?

Our team will let you know all about your options from gloss varnish to crackle varnish; matt varnish to semi-matt varnish; and spot-colour printed matt to spot-colour printed gloss varnish. Gold and clear lacquer finishes and BPA-NI (Bisphenol A Non-intent) coatings are also possible.

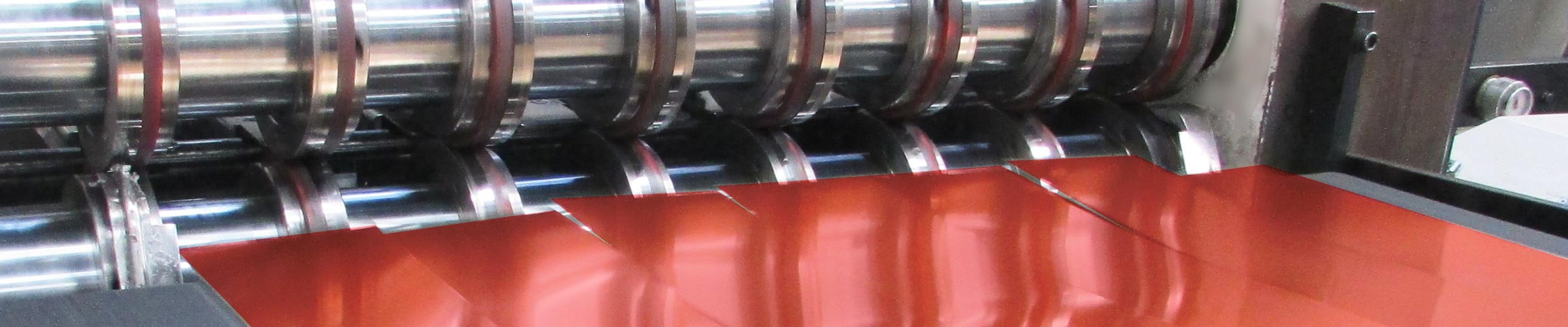

A modern high-speed coating line enables end-to-end lacquering, coating and varnishing, meaning the services that await you are of consistent quality.

A premium product is guaranteed thanks to use of innovatory equipment, rigorous quality control at every stage of the process and high-calibre coating applications.

Our efficient thermal drying oven with air purification incinerator ensures the environment is protected throughout the production process.